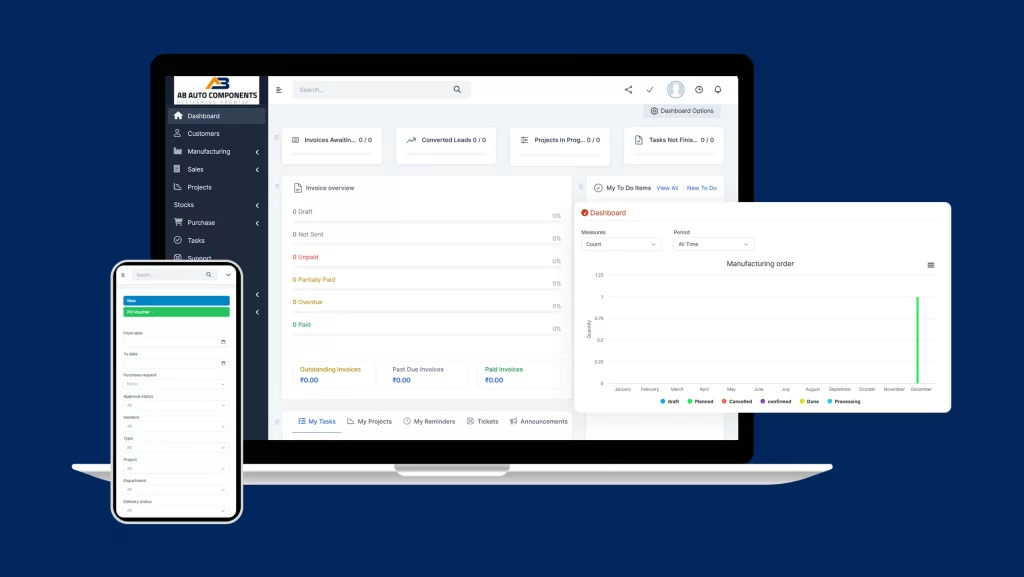

The automobile components manufacturer required a centralized ERP system to manage production planning, inventory, procurement, quality control, and dispatch operations while improving visibility across departments.

Requirement

Solution Approach

The client approached us to replace fragmented tools and manual processes with a unified ERP platform. After analysing their manufacturing workflows, our team designed a custom ERP aligned with shop-floor operations and business controls. We followed a structured approach covering solution architecture, module-wise design, development, testing, and deployment. Regular review meetings were conducted at every major milestone to ensure alignment with operational needs. Based on feedback, process improvements and system enhancements were implemented. Post-development, rigorous functional and performance testing was carried out to ensure reliability and scalability before rollout.

Tech Stack

LAMP

Services Given

Consulting | Solution Architecture | ERP Development | Testing and Deployment

Outcome

We deployed the product after multiple layers of testing and optimizations and client is very happy about our solution approach and responding to changes. With the best product in hand, client started scaling up the business with their marketing strategies. After 3 months, we received the feedback stating that the client is satisfied working with us.